Address: 405 Qinfeng South Road, Kunshan, Suzhou

Contact: Mr. Wan Qiliang

Telephone: 86-0512-57779769

Hand machine: 13776359698

E-mail: WQL_0816@163.com

Website: www.ksxinheshun.com

1. Processing of paper containers

Paper containers are containers made of cardboard used to package goods, such as cartons, grade cups, etc. The quality of evaluation-grade containers not only evaluates the quality of printing, but also evaluates the complexity and simplicity of the container's shape and processing.

The manufacturing process of paper containers is: plate making, printing → surface processing → die cutting, indentation → box making.

1. Material

Generally, it is made of cheap materials that have good printing effects and are suitable for the packaged goods. Yellow board paper, kraft paper, cardboard, white paper, etc. are used as printing materials. If the requirements are high, copperplate wires can be mounted on these materials. Paper and printing inks should also be selected according to the packaged items with light-resistant, abrasion-resistant, oil-resistant, drug-resistant, and non-toxic inks.

2. Plate making, printing

Use letterpress, lithographic, photo intaglio, and flexographic printing. Now mainly lithographic printing, letterpress printing can get a good printing effect, bright color tone, and good gloss finished product, but the plate-making process is complicated and not as simple as the lithographic printing. In the printing process, spray powder to prevent the back side from sticking and dirty.

3. Surface processing

According to needs, it can be coated with polyethylene, sticking surface film, wax coating, foil pressing, embossing and other processes, but not all products have to undergo surface processing.

4. Diecutting, creasing

(1) Die-cutting plate making

The better way to make a die-cut plate is to use plywood to make die-cut plates. First transfer the grade box pattern to the plywood, use a wire saw to sew along the tangent and fold lines, and then embed the die cutting and crease knife lines into the plywood to make a die-cut version. It has a light version, accurate dimensions, and can be stored. advantage.

It can also be controlled by a computer. The size, shape and cardboard weight of the carton are input to the computer, and then the laser movement is controlled by the computer to engrave all the tangent lines of the carton on the plywood, and the end is embedded with a knife. line.

The process flow is: drawing level box sample drawing → drawing imposition plan drawing → copying imposition design drawing → imposition design drawing transferred to plywood → drilling and sawing → embedding → making die-cut negative template.

①Draw a sample carton diagram

Draw a black and white draft knife line diagram of the carton, each with a precise size of the box, and the lines are required to be very accurate.

②Draw an imposition design diagram

According to the carton sample map and the high value of the printable paper size, the imposition design should be carried out. The imposition design should consider saving paper and facilitating automatic removal of waste edges after die cutting. Draw an imposition design drawing according to the imposition design.

③Copy the imposition design drawing

Copy two imposition design drawings, one for printing and one for die-cutting, to ensure consistency and accurate registration during die-cutting.

④ The imposition design drawing can be transferred to the plywood and can be drawn by hand or copied by photo. Manual depiction must be highly accurate.

⑤Drilling and sawing

There is a special sewing machine, which is a wire saw that moves up and down. Drill holes at the junction of the two box cores, which is convenient for threading saws and sawing along the tangent and fold lines.

The thickness of the wire saw should be compatible with the thickness of the die cutting knife line and the creasing knife line.

⑥ Embedding

Use guillotine, wire bending machine, punching machine and other machinery to break, round or bend the knife wire into various angles according to the shape of the box.

The height of the cross-cutting knife line is 23.8 mm and the thickness is 0.7 mm. The cutting line embedded on the die-cutting plate must be of the same height. The height and thickness of the crease line depends on the thickness of the paper. The height of the crease knife line is the height of the die cutting knife line minus the thickness of the paper.

After the knife line is inserted, foam rubber should be attached to both sides so that the cardboard can be ejected from the die-cutting plate.

⑦Making die-cut negative template

The negative template is to get a good seam. Paste insulating paper on the steel plate, put it in the machine, put carbon paper, and cover with a layer of cardboard. Turn on the machine to press it to get the indentation, and open the crease line on the indentation. groove.

(2) Die-cutting and creasing machine

The die-cutting machine (die-cutting machine) is generally a flat pressure type, which can automatically feed paper, automatically die-cut, and automatically take-up. The general speed is 1800-3600 sheets/hour. The electronic control device used for foreign die-cutting, the speed can reach 8500 sheets/hour, and can automatically remove the waste edges.

In addition to die-cutting, the die-cutting and creasing machine can also be used for cold-pressing concave-convex, hot-stamping flat concave-convex telephone aluminum, and hot-pressing concave-convex.

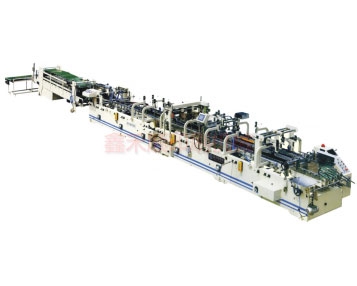

5. Box making

Fold into a carton shape with a box making machine for use in the next process.

Corrugated boxes are generally printed with flexographic printing, while pressing lines, brushing glue, or ordering with iron wires to form the shape of the box. Generally, it is folded and rotated on a plane, and it is opened into a box shape during use.